history

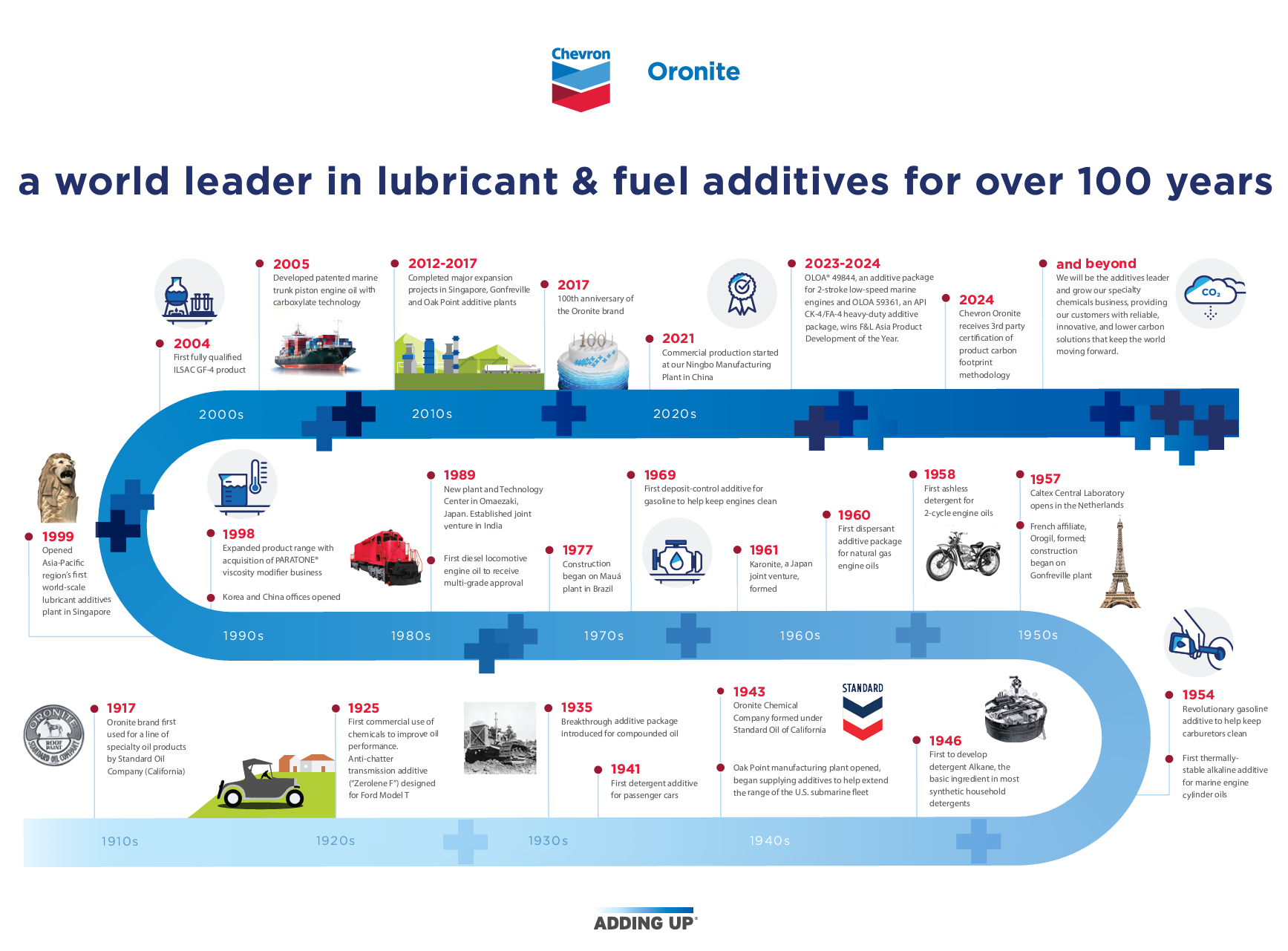

The Oronite® brand and company, derived from Spanish in reference to crude oil as “black gold,” has been synonymous with specialty petroleum-based products since 1917 when Oronite was part of Standard Oil Company (California).

Throughout its long history, Chevron Oronite has played a critical role in improving lubricant performance.

history of innovation

The Oronite® brand started over a 100 years ago as a line of specialty products. We have transitioned into a global leader developing, manufacturing and marketing quality additives that improve the performance of fuels and lubricants. We have a proud history of technological and product “firsts.” Here are some of the landmark events by decade.

One of the earliest examples of Oronite delivering value to its customers is the introduction in 1925 of Zerolene® F, an anti-chatter additive used to lubricate fabric transmission bands in the historic Model T Ford. Depicted here are five workers filling product at our Richmond Refinery.