driveline fluids

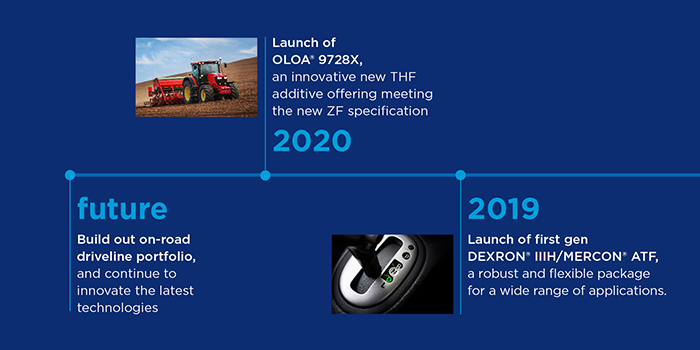

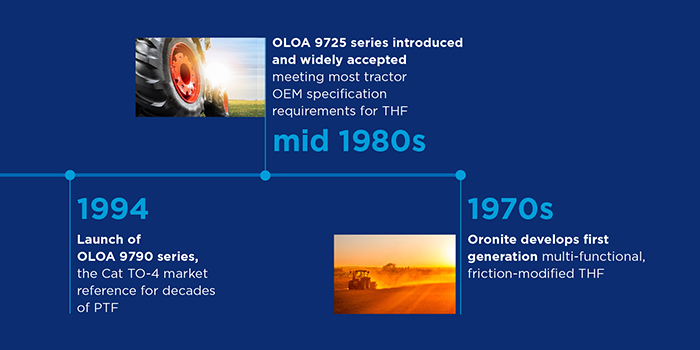

Chevron Oronite has additive solutions for all your driveline fluid needs. We are a worldwide leader in power transmission and tractor hydraulic fluid additives and have an expanding portfolio in automatic transmission fluids and gear oils. Our additives are used in factory and service fill applications, as well as market general solutions by some of the leading brands in the industry. Our global supply chain capabilities make us a reliable supplier and the strong relationships we have with original equipment manufacturers (OEMs) helps differentiate our service and expertise. We innovate and expand our technology to continually offer you products that deliver robust protection and performance.

featured media

TLT Magazine’s article titled “Bubble trouble in electric vehicle fluids," with contributions from Chevron Oronite's Rebecca Warden. View article >

Chevron Oronite's Rebecca Warden is interviewed by TLT Magazine about electric vehicles and mechanical engineering. Read article >

featured products

OLOA® 9728X is a top tier additive package designed for agricultural & construction tractors in which the fluid lubricates transmissions, brakes, and final drives, and hydraulic systems.

The OLOA® 9725XV series is a main tier package designed for common sump tractor transmissions, final drives, wet brakes, and hydraulic systems.

OLOA® 20030 is a main tier additive package designed for common sump tractor transmissions, final drives, wet brakes, and hydraulic systems.

OLOA® 20020 is a cascade package designed for common sump tractor transmissions, final drives, wet brakes, and hydraulic systems.

OLOA® 20008 is a noise suppression solution designed for common sump tractor transmissions, final drives, wet brakes, and hydraulic systems.

OLOA® 21020A is a value tier TO-4 additive product designed to formulate transmission and drive train oil.

OLOA® 9790F is a main tier additive designed for powershift transmissions, final drives and hydraulic systems.

OLOA® 21030A is a main tier additive designed for the latest generation power transmission.

OLOA® 21036A is a high tier, versatile, high performance additive for powershift transmissions, final drives and hydraulic systems.

OLOA® 24800 is a main tier cascade additive package that is recommended for use in service fill applications for automatic transmission fluid, power steering fluid, and heavy-duty applications.

OLOA® 30006 is a multifunctional gear oil solution that can be used in industrial, automotive axles and transmissions, and axles with limited slip applications.