gas engine oils

Clean-burning gas engines are a more environmentally friendly alternative than other hydrocarbon power options. Gas engines are used in different applications such as landfill, biomass, digester gas, and power generation. Gas engines that work with renewable sources can be difficult to lubricate because gases differ in composition and some specific gases (e.g., landfill gas) may contain a lot more impurities that can harm the engines. In addition to dealing with different renewable sources, many gas engines have to operate 24 hours a day, 7 days a week or in very severe conditions.

This market requires additive technology that meets the most demanding performance requirements. Field testing is an integral part of the product development process and is where we are able to gather critical data on performance of our additives. Conducting rigorous field tests and leveraging our many years of experience is just one way Chevron Oronite continues to deliver solutions that are proven in real-world conditions.

For more information about our expertise, view our video >

our expertise in gas engine oil additive technology

Chevron Oronite is recognized by global original equipment manufacturers (OEMs) as a leader in gas engine oil additive technology. We have a dedicated team of formulators and support staff that provides product development, technical support, and field test expertise worldwide. We pride ourselves on delivering additive solutions that address the challenges inherent in gas engines. Our additive solutions help maximize productivity and cost-effective operations by preserving the reliability and operating efficiency of gas engines. This is especially important for engines in remote locations where high performance is critical.

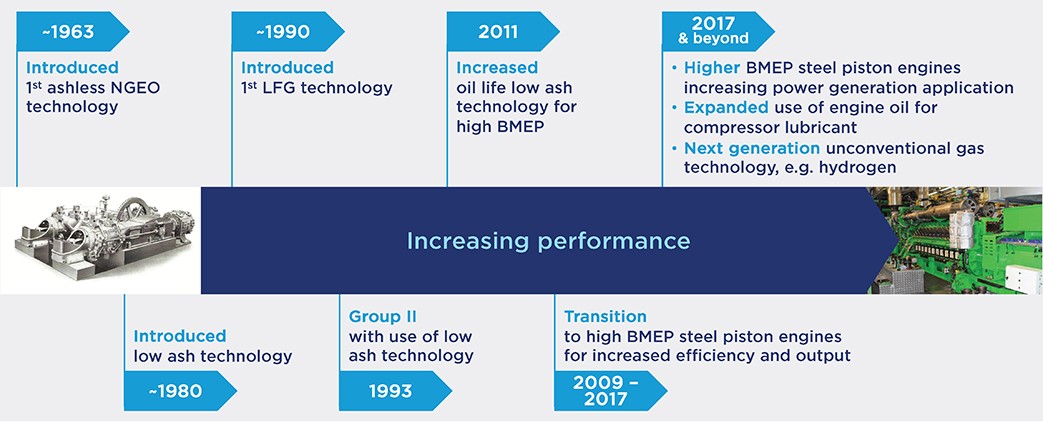

over 60 years of innovation

Since the early 1960s, we have anticipated market needs and worked closely with OEMs to provide innovative additive solutions that help improve the performance of gas engines. Our most recent additive packages were designed to support dual-stage turbochargers and high brake mean effective pressure (BMEP) steel piston engines. By improving thermal stability and detergency, our additives now allow lubricants to withstand higher temperatures, thus leading to reduced piston deposits and increased oil life.

featured products

OLOA® 46800 was developed for high BMEP, steel piston engines running on pipeline gas in stationary power generation applications.

The OLOA® 46600 series is recommended for biogas applications and running in landfill, biomass, or digester gas applications.

OLOA® 44502, 44505, 44506, 44507 are low ash additives designed for naturally aspirated turbo-charged and lean-burn gas engines in dry/sweet gas applications. They can also be boosted for engines used in biogas (digester/landfill) applications.

OLOA® 1255C is designed for use in high output, highly turbo- charged, 4-stroke engines requiring a low ash engine oil in dry/sweet gas applications.

OLOA® 46700 is designed to reduce emulsion issues in gas field compression systems such as shale gas and coal bed methane sources.

OLOA® 1299W is designed for 2-stroke engines (compression, gas gathering) burning gas and lightly loaded 4-stroke engines.