marine

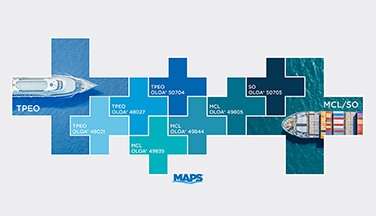

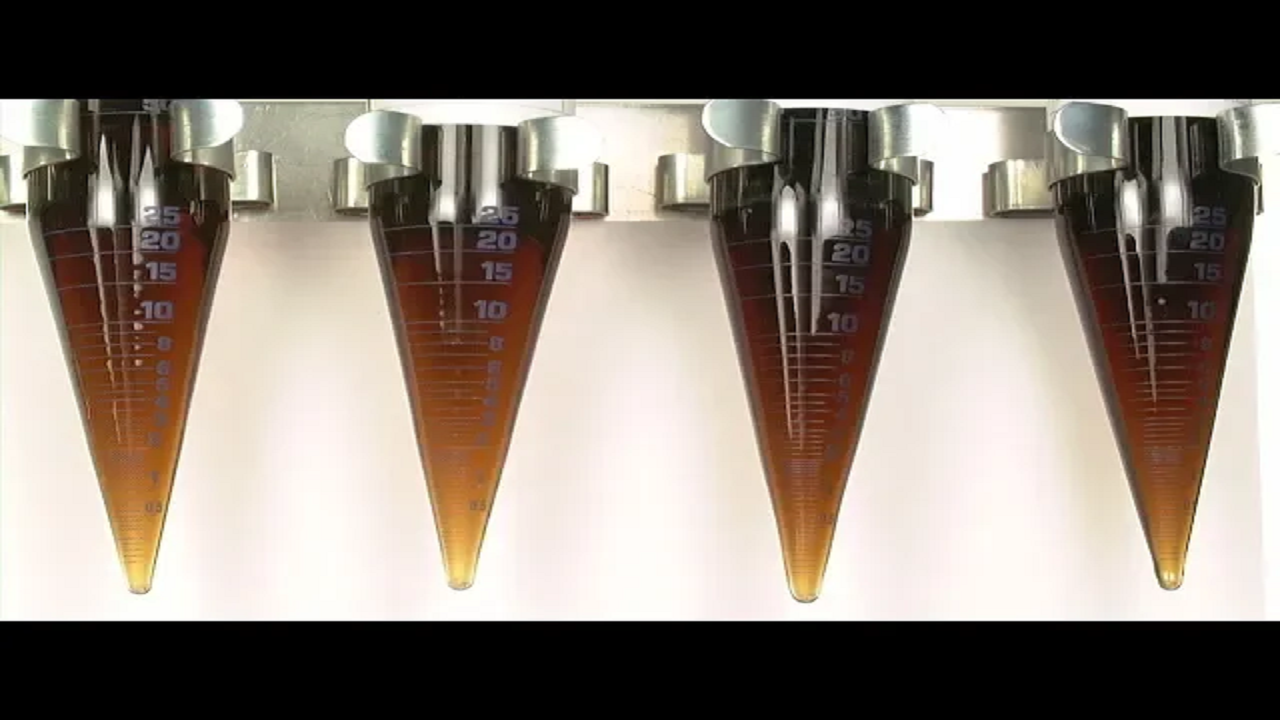

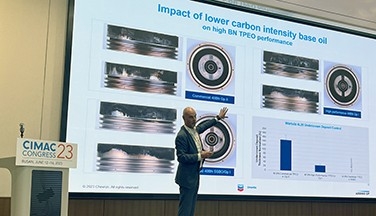

Chevron Oronite’s marine lubricant additives are designed to protect and enhance performance for a variety of engines. We’re working closely with our customers and OEMs to prepare for upcoming changes in the marine lubricants landscape driven by IMO’s 2050 lower carbon targets.